AM International remains steadfast in its commitment to a sustainable future.

“We believe that businesses must be a force for good. Our responsible practices, built on a foundation of transparency and accountability, ensure that our actions create a lasting, positive impact for all our stakeholders.”

Sustainability Highlights at AM International in 2024

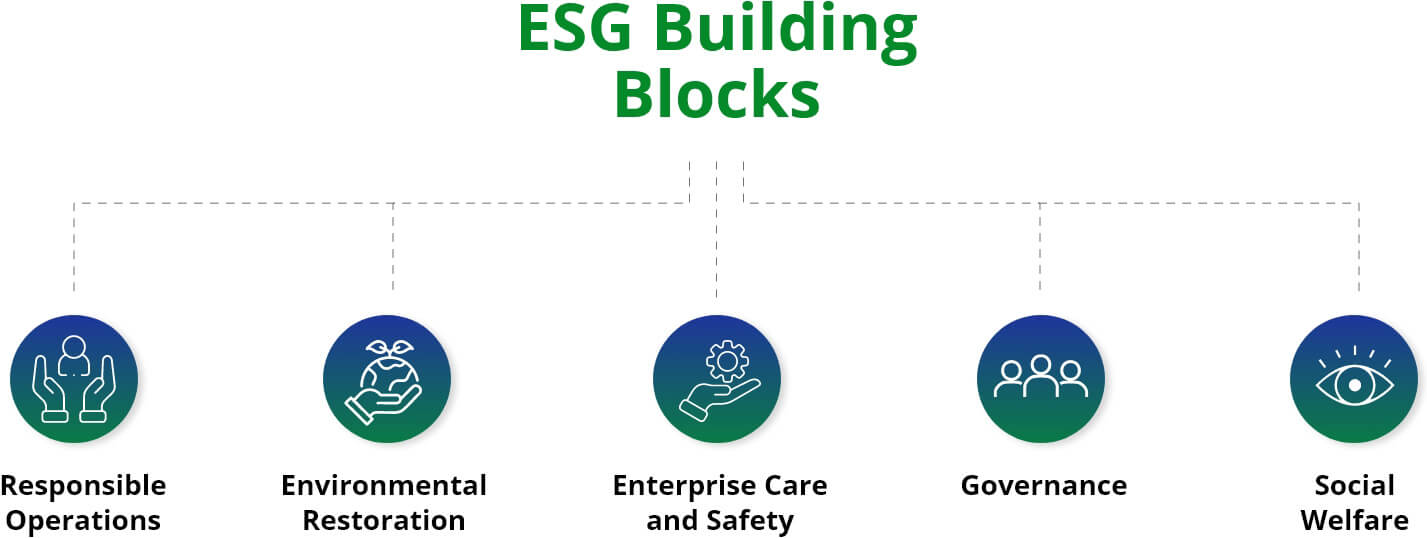

We are driven by a comprehensive framework of five foundational building blocks:

These principles shape our efforts to positively impact our stakeholder ecosystem and the environment while ensuring the economic viability of our business.

Here are the notable strides made by our group companies in 2024:

Helming Sustainable Agriculture Solutions

- Drone-based fertiliser spraying was introduced at farmer training workshops in Desur, Tiruvannamalai, and Pathukadai villages in Tamil Nadu, demonstrating precision technology for higher productivity with fewer resources.

- Upgrades to Sulphuric Acid (SA) and Urea plants, along with a new Carbon Dioxide (CO2) Recovery project, enable a transition from Grey Ammonia to Blue Ammonia, advancing sustainable operations.

- Enhancements to DiAmmonia Phosphate (DAP) plants now allow the production of 10 product grades across three families, catering to diverse agricultural needs.

Global Pioneer in Sustainable Industrial Solutions

- First company in the world to manufacture Green Ammonia in 2023.

- Aims to expand Green Ammonia production capacity to 150 MTPD.

- A ₹970 crore investment agreement was secured with the Government of Tamil Nadu at the 2024 Global Investor Meet in Chennai in pursuit of this goal.

Optimising Energy Usage

- Planted 5,000 trees across 5 acres in the Heavy Chemicals Division (HCD) plant.

- Renewable energy usage increased from 42% in FY23-24 to 61% by October 2024, demonstrating a strong shift towards sustainable energy sources.

- Switching from furnace oil to RLNG for heating requirements achieved a 95% reduction in Sulphuric Oxide (SOx) emissions and a 16% decrease in CO2 equivalent emissions.

- Converting fuel oil to RLNG in the Captive Power Plant (CPP) led to an annual CO2 emissions reduction of 20%.

Harnessing Energy Efficiency

- Continuous efforts in energy conservation highlight focus on reducing operational costs and environmental impact.

- Vapour Absorption Machines commissioned in Plant II and Plant I recover waste heat from hot effluent water, saving 1,500 power units daily.

- New screw-type air compressors with VFDs optimise power consumption, saving an estimated 50 power units per hour.

Embracing Renewable Energy

- Solar panels installed at Coventry plant replace approximately 30% of conventional electricity usage.

- The solar initiative is expected to prevent around 67,881 kilograms of CO2 emissions annually.

- This effort demonstrates Notedome’s commitment to sustainable operations and cleaner energy alternatives.

Enhancing Sustainability Compliance

- PennWhite actively participates in industry initiatives like EcoVadis and IntegrityNext, ensuring alignment with global sustainability standards.

- By integrating sustainability in its production, PennWhite meets customer needs while supporting environmental goals.

These efforts by our group companies exemplify our commitment to creating a sustainable future. By aligning innovation with responsibility, we aim to lead by example and inspire change across the sectors in which we operate.