Today, the recurring theme among corporations is one of ecological costs. More and more businesses around the world are now working to minimize carbon costs, introducing green technologies to manufacture and produce. The most major environmental challenge is controlling carbon emissions, as greenhouse gas (GHG) is causing global warming and a climate imbalance.

Carbon Capture:

Switching from fossil fuels to green fuels such as hydrogen and natural gas can significantly reduce one’s carbon footprint but it’s not enough. Companies are also using high-tech carbon-capture technology to extract carbon dioxide from the point of emission. The captured carbon is then compressed, transported and stored, and used in one of two ways – it is either injected into deep geological formations such as depleted oil and gas reservoirs, or used in the production of fertilisers, synthetic fuels and building materials, among other things.

AM International’s operating companies are relentlessly implementing an ESG (Environmental, Social, Governance) strategy, and leveraging technology to achieve carbon neutrality. For instance, Tuticorin Alkali Chemicals & Fertilizers Limited has established a global milestone in sustainable manufacturing with the production of green soda ash, an ingredient in products of everyday use. It arrived at this breakthrough when it starts producing the green chemical at its plant in Thoothukudi, Tamil Nadu.

Another AMIH group company, Manali Petrochemicals Limited (MPL), has tied up with UK-based Econic Technologies to make eco-friendly polyols. Harnessing the power of science and innovation, MPL has retrofitted its production facility in Chennai to make CO2-containing polyols, thus reusing carbon and reducing GHGs.

Zero Liquid Discharge (ZLD):

This widely used sustainable practice involves the treatment of waste water generated by industrial processes, whereby solid waste is extracted and disposed of responsibly, and the water that remains is reused, for instance, in irrigation. This process, of recycling waste water and reusing it, results in Zero Liquid Discharge or ZLD. Most of the factories across our operating companies are implementing ZLD as part of AMIH’s ESG strategy. For instance, Tamilnadu Petroproducts Ltd has commissioned a Reverse Osmosis plant, which treats the effluents generated by its Linear Alkyl Benzene plant, and reuses the water thus produced.

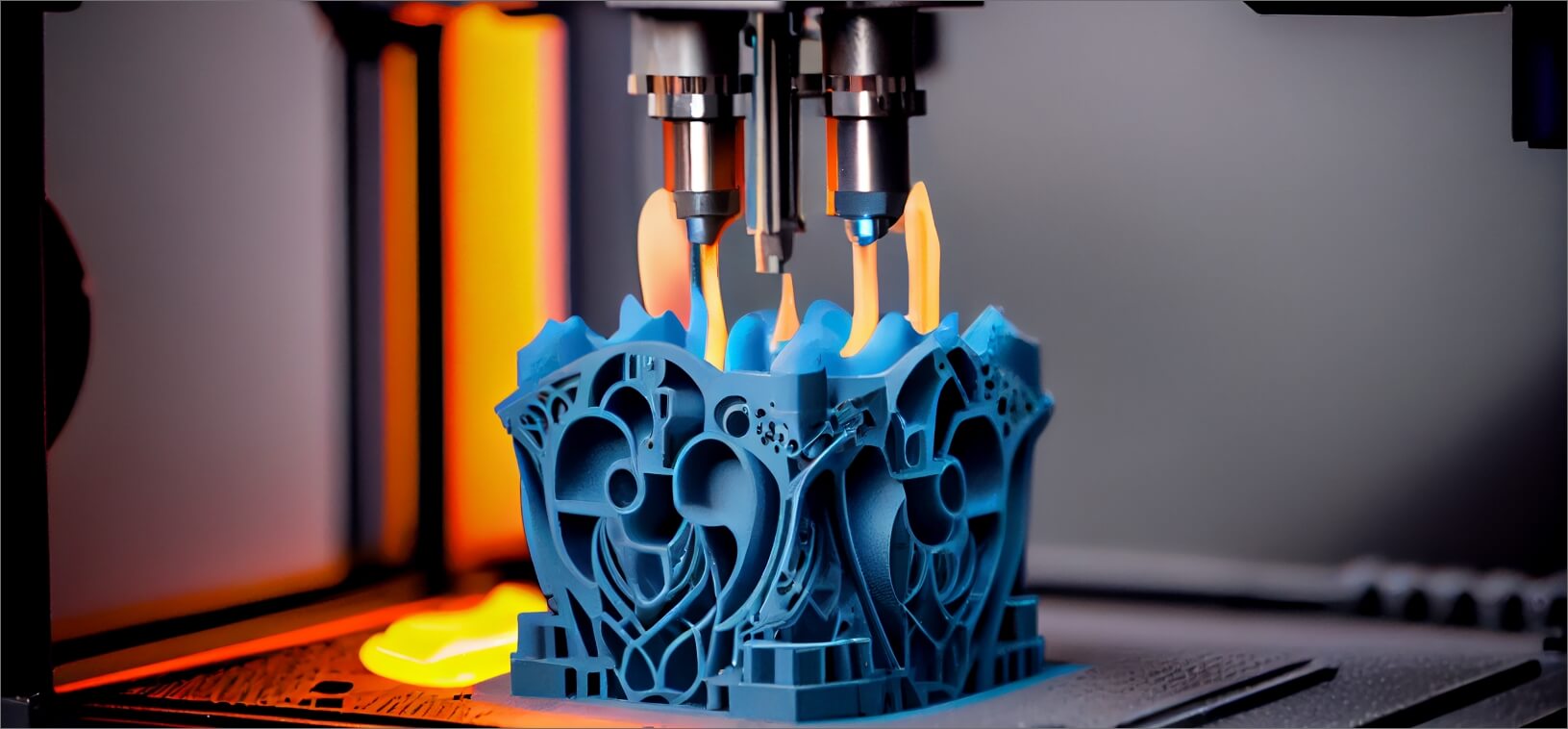

3D Printing

This technology has captured the imagination of engineers and the general public, but does it promote environmental sustainability? Those who count 3D printing as green tech point out that it involves zero wastage of raw materials as the process builds products layer by layer, thus using the exact amount of material needed. Also, 3D printing consumes less power than traditional manufacturing processes, which often deploy wasteful techniques as part of the production process. Besides, printed objects can often be made in situ, eliminating the carbon footprint generated by transportation. The technology can also be used to make limited quantities of a product, further reducing wastage. From specialty chemicals to jet engine components, to hearing aids, to doorknobs, 3D printing is still showing us what it is capable of.

The good news is that more and more businesses are adopting green technologies to repay their environmental debt. Let us pull together and vigorously pursue our ESG goals to address the concerns of a planet that needs our help.

Implementing an ESG strategy is no longer an option; it is an essential part of doing business as it reduces input and operational costs. It also forges a sustainable connection with customers, vendors and the public, which circles back to business gains.