Although 70 percent of the planet is covered with water, access to clean and adequate water for everyone is a key goal that all of us should work towards. UNICEF warns that if we fail to address this concern, half of the world’s population will face water scarcity by 2025.

Industrialization requires water for its day-to-day running. However, factories and production units should work towards efficient water usage, thus contributing to water conservation.

AM International businesses are actively committed to sustainability, recognizing it as an imperative rather than an option. This commitment is reflected in a range of initiatives across the group, be it Southern Petrochemical Industries Corporation’s (SPIC) Desalination Project or Tamilnadu Petroproducts’ (TPL) Rainwater Harvesting systems at the plant and community wells that have been in place for several years now.

Here are some best practices from our experience in water management in manufacturing:

Water Metering:

Water metering ensures that the working of all manufacturing equipment is optimized and there is no scope for leakages. AM International companies maintain responsible water usage by implementing water metering.

This brings water-saving opportunities to light by addressing the critical issue of water loss due to unnoticed leaks.

Industrial Rainwater Harvesting:

Manufacturing units use about 12% of the public water supply. However, a gradual reduction of this dependency is necessary to ensure adequate water supply to households.

Industrial Rainwater Harvesting is an effective measure of addressing this situation. The idea here is to collect, store and filter rainwater. As a result, the same water becomes usable by manufacturing units around the year for non-potable purposes.

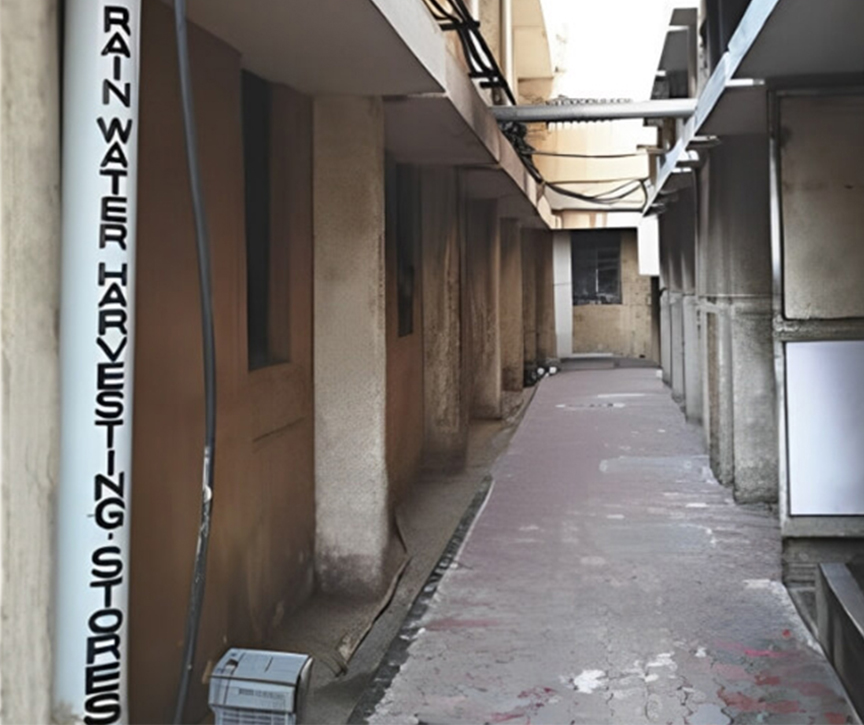

TPL has successfully implemented industrial rainwater harvesting by establishing rooftop facilities at their plant and office building to collect and store rainwater in reservoirs for year-round use. Additionally, TPL has converted several unused community wells into rainwater harvesting systems in Chennai’s Mathur or Periya Mathur area.

Wastewater Treatment & Zero Liquid Discharge (ZLD):

When it comes to effective water management practices, we must recognize the contribution of wastewater treatment.

This involves reducing wastewater dispensed from the plant and producing clean water suitable for reuse. It is where TPL’s Zero Liquid Discharge (ZLD) initiative has helped reduce freshwater usage by tapping on the Reverse Osmosis plant.

The process here involves treating effluent generated from the LAB plant and reusing it to achieve ZLD.

Importance of ESG in Manufacturing

As sustainability and ethical business practices become vital priorities, manufacturing companies must focus on ESG (Environmental, Social, and Governance) goals.

Water is an essential but scarce resource. Its management is critical for the sustainability and survival of businesses and communities. It makes ESG considerations about water usage particularly important in manufacturing. Adopting sustainable practices in water management can provide numerous benefits in manufacturing, including reducing water usage and waste, increasing efficiency, strengthening reputation, and enhancing stakeholder relationships.

By prioritizing ESG in water management practices, companies can build a sustainable and resilient business while mitigating water scarcity and pollution risks and contributing to a healthier planet.

Our group companies, TPL and MPL, have been frontrunners in replacing freshwater usage with recycled water. TPL has signed an MoU with Chennai Metropolitan Water Supply and Sewage Board to run operations using recycled water from Tertiary Treated Reverse Osmosis.

SPIC has demonstrated its commitment to sustainability by establishing a desalination plant on its premises, which supplies 10 million litres of water daily to meet the needs of in-house operations and nearby communities.

It aligns with Goal 6 on the United Nations’ list of 17 Sustainable Development Goals – Water and Sanitation. The objective is to provide safe water access to every individual globally.

The manufacturing industry must adopt a stakeholder-centric approach that prioritizes environmental, social, and governance concerns. Our group companies have demonstrated success in this area.

It is critical for manufacturing units to adopt a more sustainable approach, closely monitor their water usage, and make efforts to treat industrialized wastewater.

On World Water Day, let’s reaffirm our pledge to work towards water conservation, recycling, and zero liquid discharge goals.